Invest Nord Service Sp. z o.o. is a company with many years of experience, operating since 2014 in the shipbuilding, offshore, and onshore industries. We specialize in two main areas of activity: production and shipyard services. We carry out projects both on the Polish market and in demanding foreign markets, including Germany, the Netherlands, Sweden, Norway, Denmark, Switzerland, Wales, and China.

Our advantage lies in the combination of a modern machine park with an experienced team of specialists, which enables us to execute complex and precise orders — from simple steel elements, through prefabrication, to complete steel structures and industrial installations. We serve the shipbuilding, offshore, energy, construction, and industrial sectors, delivering comprehensive solutions in accordance with international quality and safety standards.

We operate with full commitment at every stage of execution — from the analysis of technical drawings, through planning and optimization, to production, assembly, and delivery logistics. Our solutions reach offshore platforms, industrial plants, energy installations, vessels, and construction projects throughout Europe and Asia.

We focus on quality, timeliness, and flexibility, which allows us to build long-term relationships based on trust and professionalism. This enables us to successfully support clients in Poland and abroad, adapting to their individual needs and requirements.

Nord Service Sp. z o.o. is a reliable and proven partner for the industry, offering comprehensive production and service support, ensuring safety, precision of execution, and full quality control at every stage of cooperation.

We work for:

Over 10 Years of Industry Experience

We have been operating in the market for over a decade, gaining valuable experience in the shipbuilding, offshore, and onshore industries. Our many years of practice allow us to carry out even the most demanding projects with full professionalism. Trust a company that combines tradition with modern solutions.A Team of Qualified Specialists with Diverse Skills

Our team consists of qualified experts with a wide range of specializations who ensure the highest quality of services provided. Thanks to their commitment and experience, each project is carried out precisely and efficiently. We focus on development and continuous improvement of our employees’ qualifications to meet market expectations.Comprehensive Project Support — From Planning to Final Acceptance

We provide complete project support — from initial consultations and planning, through execution, to professional final acceptance. Our support guarantees a smooth workflow and timely completion of the investment. Thanks to our comprehensive approach, our clients can focus on their business, confident that the project is in the best hands.Flexibility and Adaptation to Client Needs

We tailor our services to the individual requirements of each client, offering custom-made solutions. Our flexible approach allows us to carry out both large investments and smaller, specialized orders. We build partnerships based on trust and open communication to always meet our clients’ expectations.Operation in Accordance with International Standards

We work in full compliance with applicable norms and international quality standards, ensuring the safety and reliability of our services. Our operations cover markets in Poland, Norway, Scandinavia, and China, where we successfully complete demanding projects. We focus on transparency and the highest industry standards to build lasting relationships with clients.Quality and Timeliness

The highest quality of services we provide goes hand in hand with reliability and on-time delivery. We ensure that every stage of the project runs smoothly and that the results meet our clients’ expectations. This earns us trust and positive recommendations in demanding European and Asian markets.Certificates and References

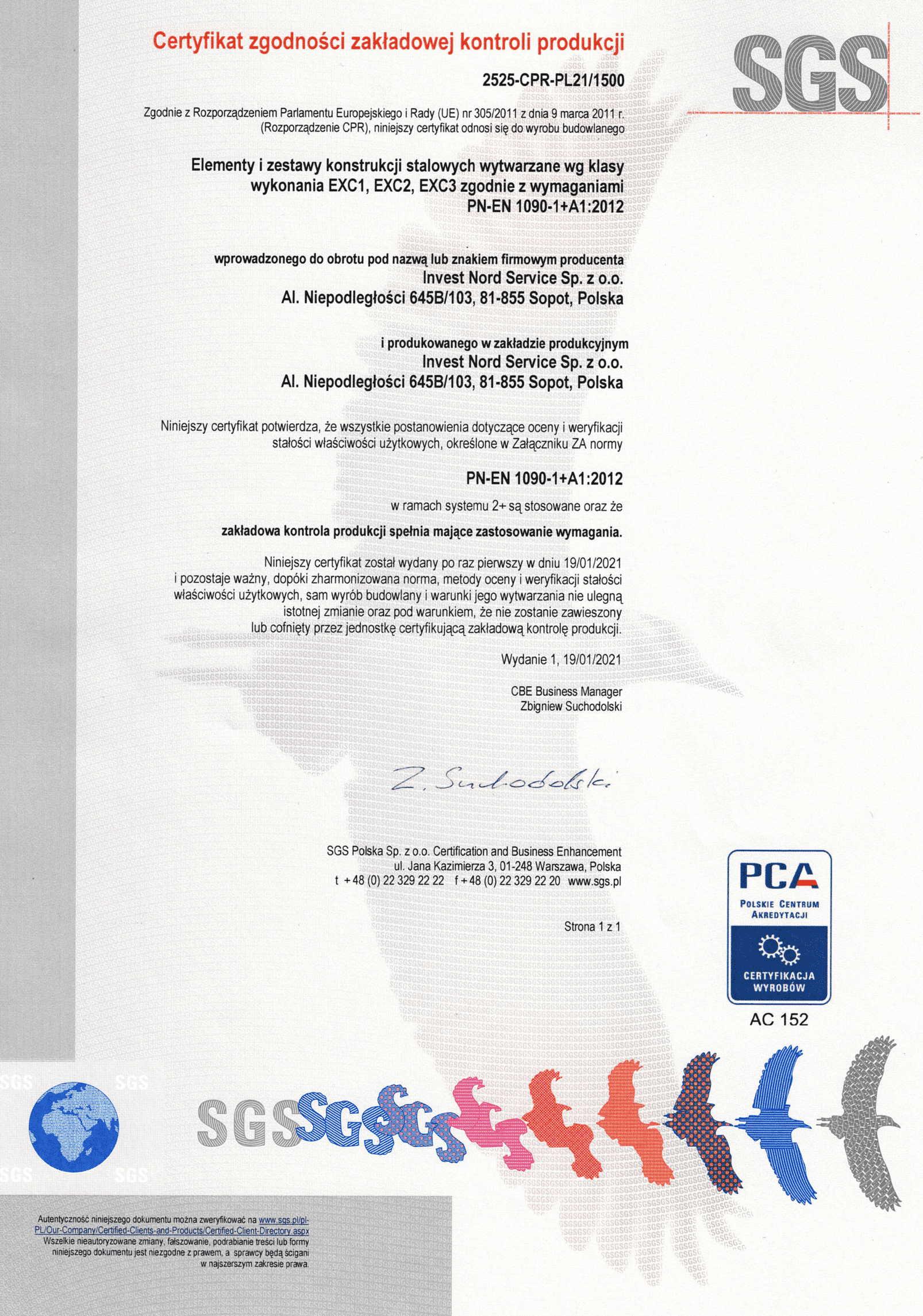

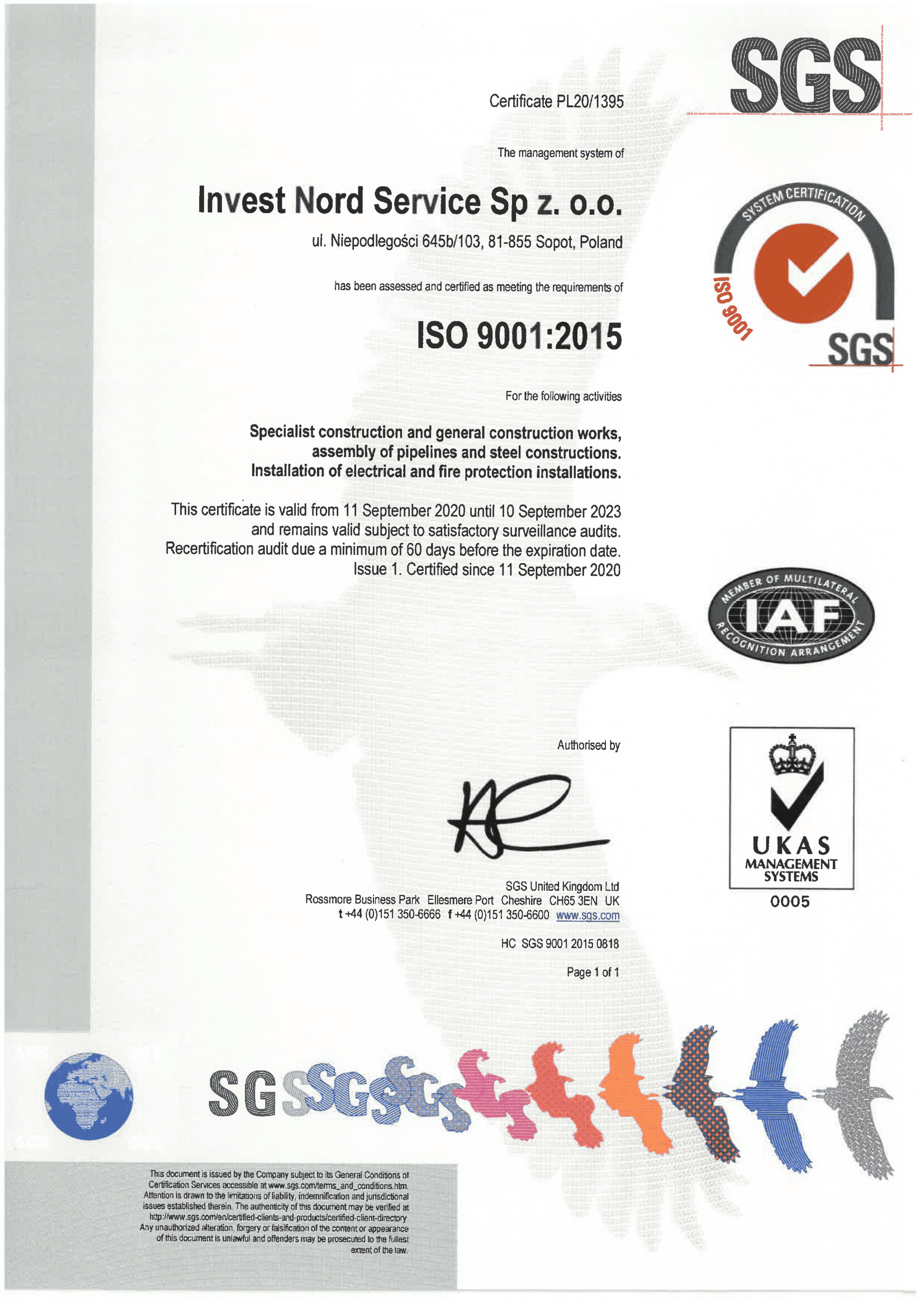

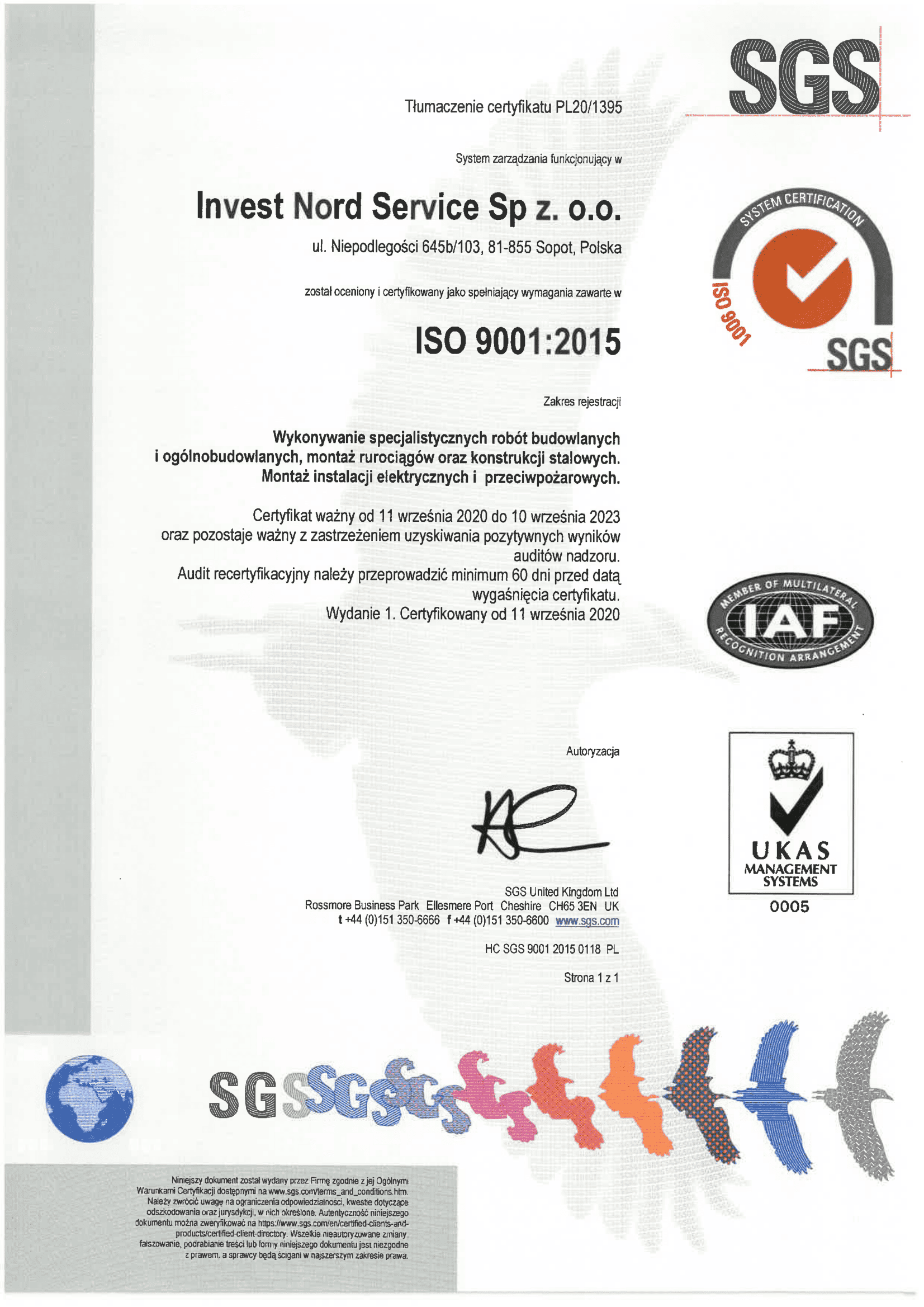

We hold numerous certificates confirming the high quality of our services and compliance with international standards, including the ISO 9001 certificate. Our competencies have also been repeatedly confirmed by business partners in the form of references. This allows us to build trust and long-term relationships with clients from various industries. We continuously focus on development, process improvement, and meeting the requirements of even the most demanding contractors. Documents confirming our qualifications are available upon request.Join Our Team!

We are looking for qualified employees to work in the shipbuilding and industrial sectors. We offer stable employment, attractive conditions, and professional development.

Contact

Piping Works

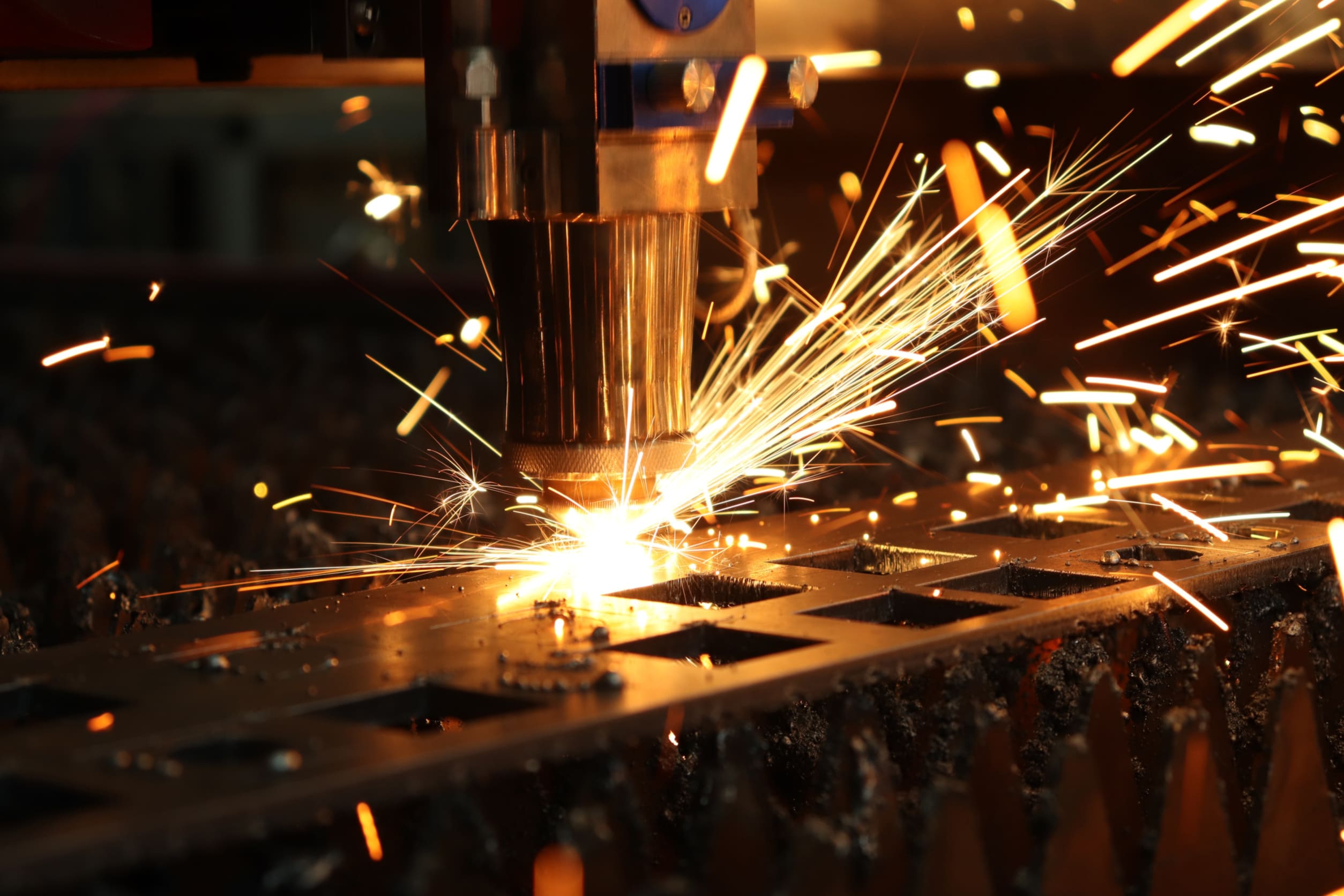

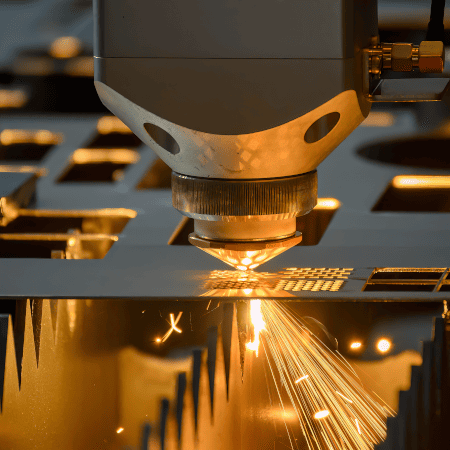

We offer precise laser cutting of black steel, stainless steel, and wear-resistant steel sheets.

We have a modern laser with a working area of 2500 × 8000 mm and the ability to cut material up to 75 mm thick.

The use of a bevel head allows cutting at an angle of up to 65°, enabling the production of complex details and the preparation of elements for further processing, such as welding.

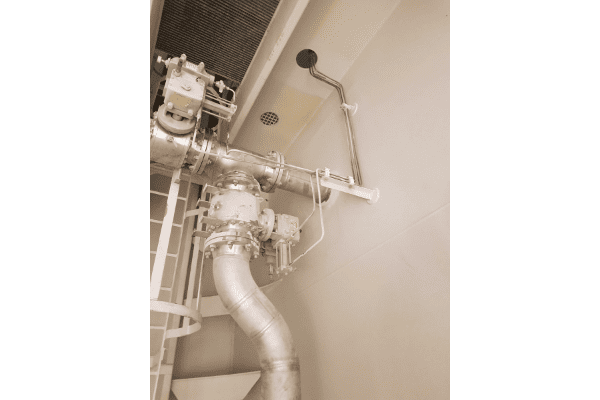

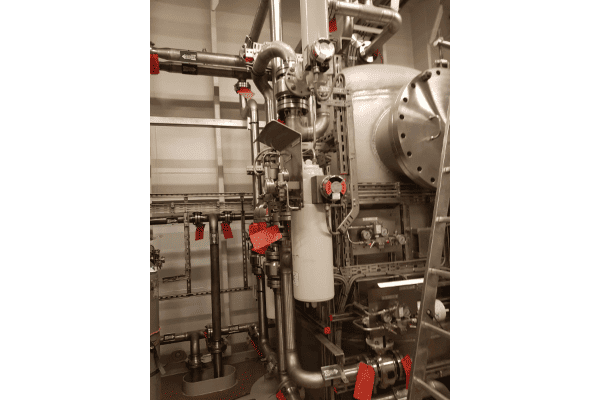

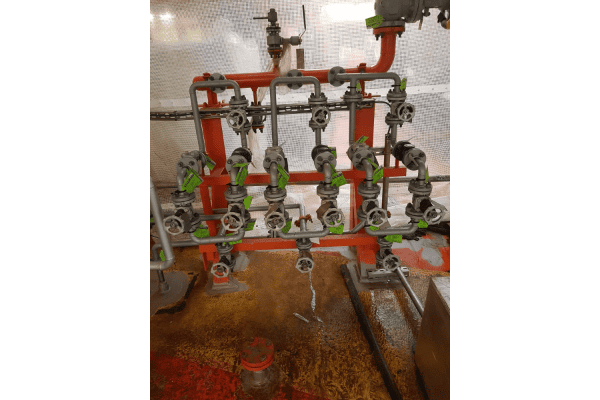

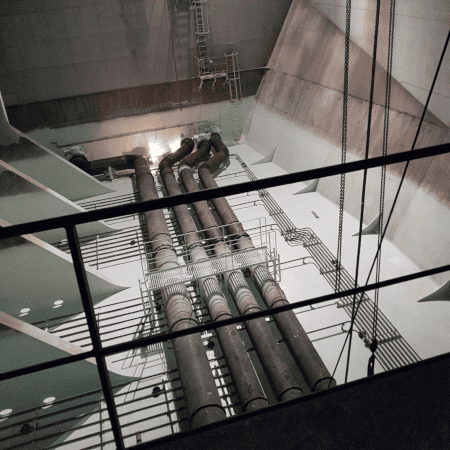

We carry out comprehensive piping, assembly, and welding works for the maritime, offshore, and land-based industrial sectors.

We specialize in the prefabrication of pipelines from black steel, stainless steel, and CuNiFe, as well as their installation and welding on all types of ship systems,

such as fuel, cooling, spraying, fire-fighting, heating, sanitary, and ballast systems.

We offer full project and consulting support — from conceptual design to delivery documentation.

We also perform modernizations and repairs of piping systems as well as leak tests of pipes and tanks.

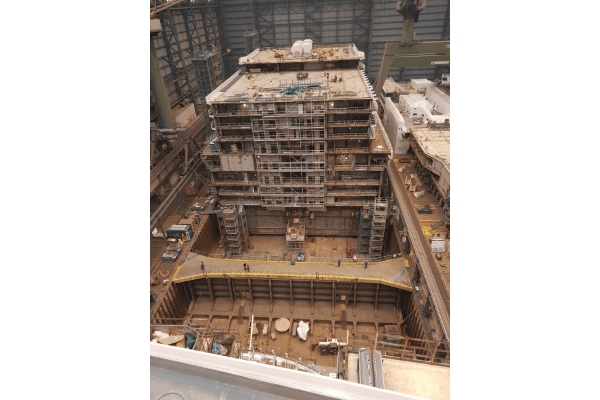

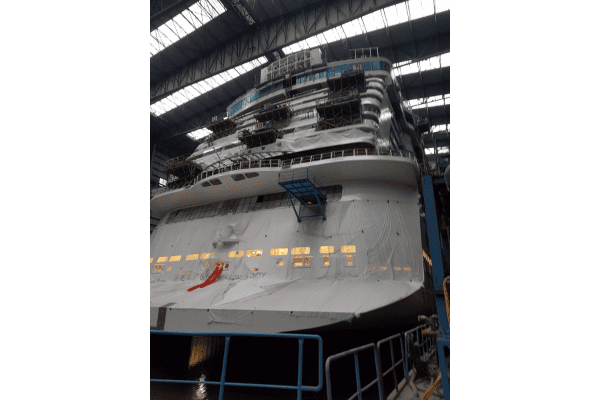

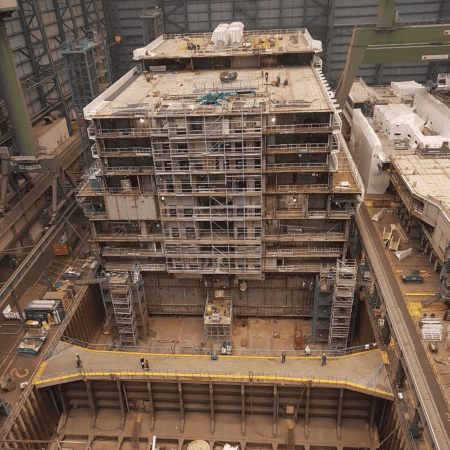

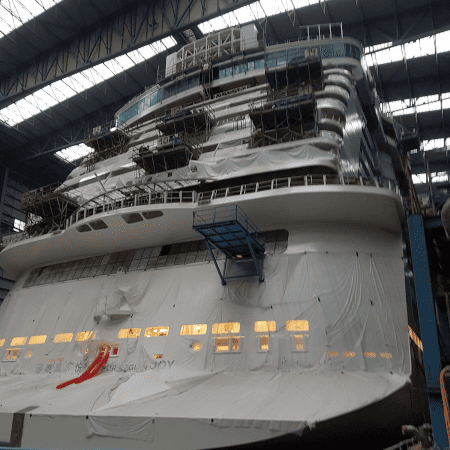

Hull Works

A solid structure is the foundation of every ship’s safety.

We carry out comprehensive work in the construction and modernization of hulls, ensuring quality, durability, and compliance with international standards.

We handle the construction, reconstruction, and modernization of ship hulls as well as all work related to the assembly of hull sections. We perform prefabrication and assembly of elements from various types of steel and aluminum. Our services also include welding of ship sections in compliance with applicable standards, tank leak testing, and preparation for technical inspections. We provide professional advice and supervision during project execution, as well as cutting elements for transport or repair purposes.

Metalworking

Precise execution of structural and equipment elements.

Through our metalworking services, we ensure the durability and reliability of key structural and equipment components for ships and industrial facilities.

We carry out comprehensive metalworking tasks in the construction and repair of hull elements as well as in the installation of equipment for ships and industrial structures. We install frames, brackets, foundations, ladders, and other structural elements. We also prepare surfaces for welding, ensuring durability and high-quality workmanship.

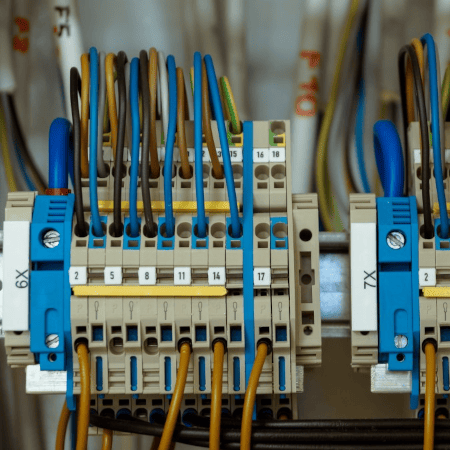

Electrical Works

Modern electrical systems for ships and industrial facilities.

We handle the design, installation, and servicing of electrical installations, ensuring the reliability and safety of all systems.

We provide comprehensive services in the field of electrical installations on vessels and in industrial facilities. We carry out the laying and fastening of new cable routes, design their layout, install monitoring systems, control cabinets, lighting, and electrical devices such as sockets, switches, and thermostats. We also ensure professional sealing and securing of cable penetrations.

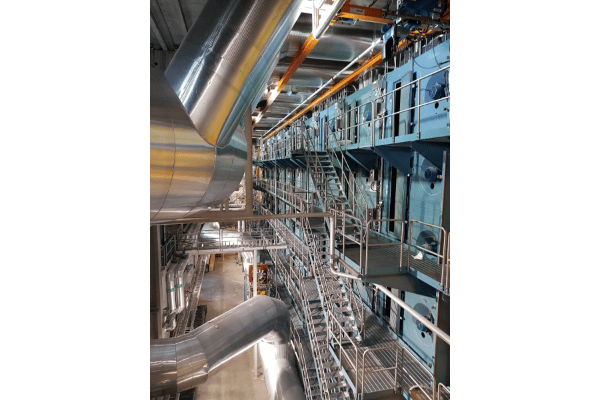

Insulation Works

Effective insulation means comfort, safety, and energy savings.

We provide professional insulation services for both land-based and maritime industries, tailored to the specifics of each project.

We offer a full range of insulation services for maritime and land-based industries. We perform thermal, fire, and acoustic insulation for pipelines, ventilation ducts, exhaust ducts, and technical rooms. We protect flat surfaces and installations in accordance with applicable standards, increasing safety, comfort, and energy efficiency.

Production and Installation of Steel Structures

Steel structures tailored to the needs of industry.

From design to installation — we deliver solid, durable, and certified steel structures for the maritime, energy, and industrial sectors.

We specialize in the production and installation of a wide range of steel structures — from passenger boarding bridges, technical and emergency stairs, to containers, platforms, railings, as well as power poles and noise barriers. We manufacture both standard and custom-made structures. We provide a complete service: production, transport, on-site installation, and necessary quality testing. Thanks to our team of certified specialists and modern technical facilities, we carry out non-destructive testing (VT, UT, MT, PT, RT, AT, ET, LT) and technical supervision both domestically and abroad. We also offer anti-corrosion protection through painting in accordance with EN ISO standards and hot-dip galvanizing.

Laser Cutting

We provide precise laser cutting services for sheets of all steel grades. We operate a modern 20 kW machine with a working area of 2500 x 8000 mm, capable of cutting carbon steel up to 75 mm thick. The 3D bevel cutting head allows cutting at angles up to 65° (subject to verification – parameters), enabling the production of even the most demanding details.

Carbon steel recommended thickness 40.0 mm – Maximum thickness 50.0 mm

Stainless steel recommended thickness 35.0 mm – Maximum thickness 40.0 mm

Aluminium recommended thickness 20.0 mm – Maximum thickness 40.0 mm

Brass recommended thickness 15.0 mm – Maximum thickness 20.0 mm

We specialize in precision laser cutting of sheets from all types of steel — carbon, stainless, and wear-resistant. Our advanced machinery includes a laser with a working area of 2500 x 8000 mm, capable of cutting material up to 75 mm thick. Equipped with a bevel head, it allows cutting at angles up to 65°, enabling the creation of complex shapes and preparing details for welding. We offer fast turnaround times, high cutting quality, and repeatability even for large production batches.

Our company offers modern laser cutting services for sheets of all steel types: carbon, stainless, and wear-resistant. We have an advanced laser machine with a working area of 2500 x 8000 mm, allowing us to cut materials up to 75 mm thick. Thanks to the use of a bevel head (cutting at angles up to 65°), we can precisely prepare elements for further processes such as welding or machining. This solution allows us to carry out both standard projects and custom orders with a high level of complexity.

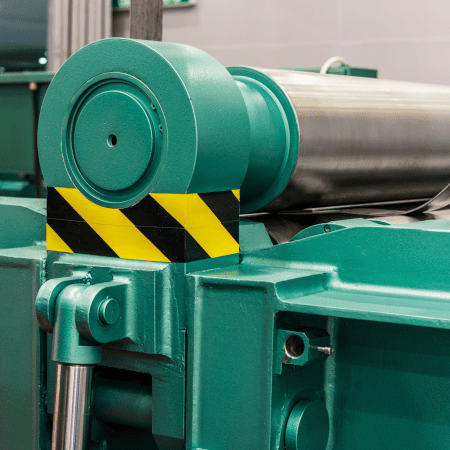

Plate Rolling

We offer plate rolling services for thicknesses ranging from 4 mm to 32 mm, with a maximum working width of 3000 mm. We work with both carbon and stainless steel. Thanks to modern equipment, we ensure high quality and repeatability of rolled elements.

We operate a plate rolling machine with a working width of 3000 mm, capable of rolling plates from 4 mm to 32 mm thick. We work with carbon and stainless steel, offering a wide range of diameters and shapes—from light rolls to heavy industrial cylinders. Our experience and precision allow us to handle both standard and custom orders for the energy, chemical, food, and construction industries.

We provide plate rolling services for steel sheets in the range of 4 mm to 32 mm thickness and up to 3000 mm width. We work with both carbon and stainless steel, producing elements of various diameters and bending radii. Rolling is performed on modern equipment, ensuring high dimensional accuracy and repeatability even for large production runs. Our production capabilities are tailored to the needs of industries such as heavy, construction, energy, and petrochemical sectors.

Pipe Rolling

We offer steel pipe rolling services in various diameters and wall thicknesses. The process is carried out with high precision using carefully selected tools and technologies. We work with both stainless and carbon steel, in accordance with client requirements and applicable industry standards.

Pipe rolling is one of our specializations. Thanks to modern equipment and an experienced team, we ensure top quality, repeatability, and the ability to produce pipes with various bending radii and lengths. We guarantee fast delivery times and flexibility to adapt to individual projects.

We carry out pipe rolling for industrial installations, pipelines, steel structures, and pressure vessels. The process is based on proven cold-rolling or hot-rolling technology (depending on the material and project). We maintain full compliance with EN, ASME standards, or client-provided documentation.

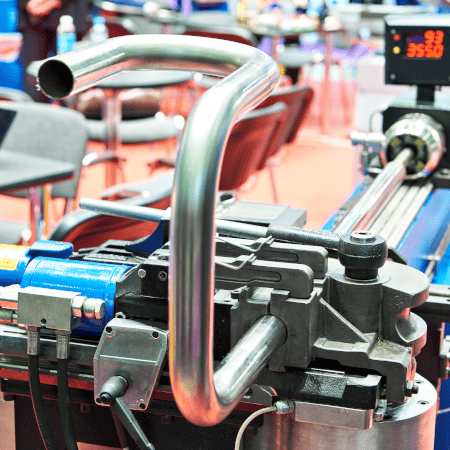

Pipe Bending

We specialize in bending pipes with diameters from DN 50 to DN 200. We handle orders for pipes made of carbon steel and stainless steel, ensuring high precision and bending quality. Our solutions are used in many industrial sectors.

We offer pipe bending services for steel pipes with diameters from DN 50 to DN 200. We carry out orders for pipes made of carbon steel and stainless steel, maintaining high precision and compliance with technological standards. Thanks to modern tools and an experienced team, we can handle the most demanding projects — both one-off and serial production.

We perform bending of steel pipes with diameters DN 50–DN 200, made of both stainless steel and carbon steel. Our technological facilities allow for precise bending while maintaining the full structural integrity of the material. The process is carried out in accordance with the highest quality and accuracy standards. We offer production flexibility — handling both single-unit projects and large-scale industrial orders.

Head Production

We produce heads with diameters ranging from 800 mm to 5000 mm. We specialize mainly in processing stainless steel, carbon steel, and titanium.

Our offer includes flat, torispherical, conical, and elliptical heads in accordance with DIN 28011, DIN 28013, and ASME standards, used in pressure vessels, heat exchangers, and industrial installations. We guarantee high quality and precision in compliance with pressure and storage industry standards. We also produce custom-designed heads after prior consultation to confirm feasibility.

We manufacture steel heads with diameters from 800 mm to 5000 mm. We produce heads from carbon steel, stainless steel, and titanium — according to applicable standards and customer requirements. Our range includes various types of heads (flat, torispherical, conical, elliptical), used in pressure vessels, heat exchangers, and industrial installations. We guarantee high quality, dimensional accuracy, and durability of the finished components.

We specialize in the production of steel heads with diameters from 800 mm to 5000 mm. We offer heads made of carbon steel, stainless steel, and titanium — in various geometric configurations, compliant with applicable standards and technological requirements. Our heads are used in pressure vessels, reactors, heat exchangers, and industrial installations. We guarantee high-quality workmanship, compliance with documentation, and timely delivery.

Prefabrication of Steel Structures and Pipelines

We carry out prefabrication of structural elements and pipelines made of black and stainless steel. We offer comprehensive service: from cutting, bending, and welding to assembly and preparation for transport. We work according to the client’s technical documentation and current quality standards.

Our company offers comprehensive prefabrication of steel structures and pipelines — regardless of project scale. We ensure high quality, on-time delivery, and a flexible approach to technical specifications. Thanks to our skilled team and advanced production facilities, we are able to meet even the most demanding project requirements.

We specialize in the prefabrication of complete steel structures and industrial pipeline systems. We perform cutting, bending, welding, finishing, and trial assembly. We work with industries such as energy, chemical, water and sewage, and processing. We guarantee compliance with EN 1090, ISO 3834, and other industry standards.

Hull Prefabrication

We prefabricate hull elements according to the client’s documentation. The process includes preparation and joining of plates and profiles, welding of the skeletal structure and plating, as well as quality control of the finished components.

Thanks to many years of experience in heavy-duty work, we offer professional hull prefabrication for industrial, maritime, and specialized applications. Our facilities allow us to produce large modules with the highest precision and quality.

We perform prefabrication of hull sections for vessels and industrial equipment. We offer the production of large steel segments with weld, leak, and dimensional control. We handle projects in compliance with classification standards (DNV, ABS, PRS) and shipyard specifications.

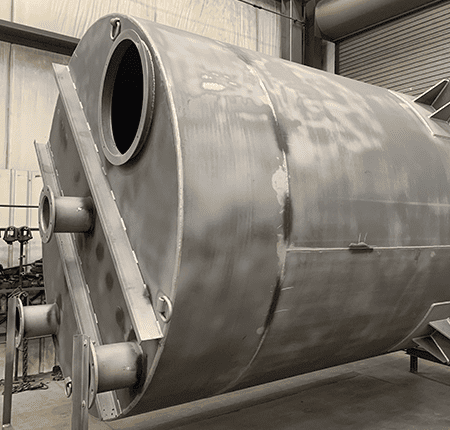

Tank Prefabrication

We specialize in the prefabrication of steel tanks of various diameters and purposes. We manufacture individual components: tank heads, shells, nozzles, as well as section assembly. We work with black steel, stainless steel, and specialized materials.

Tank prefabrication is one of our key services. We produce tank components with diameters of up to 5 meters, in accordance with project documentation and the client’s technological requirements. We ensure high-quality workmanship, technological control, and full logistical support.

We carry out prefabrication of technological and storage tank components in compliance with EN 13445, ASME, or PED standards. We work with various materials: black steel, stainless steel, duplex, and titanium. We guarantee weld quality, compliance with project requirements, and the possibility of on-site installation for the client.

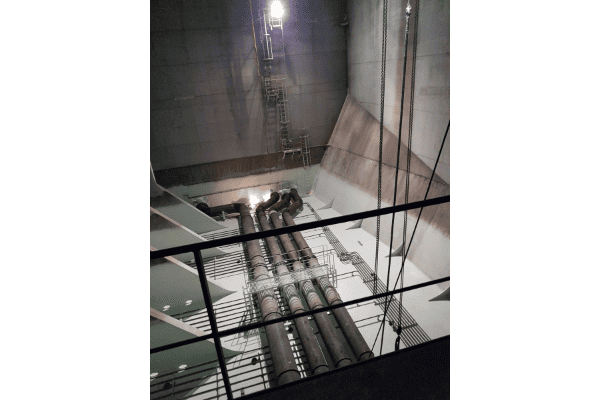

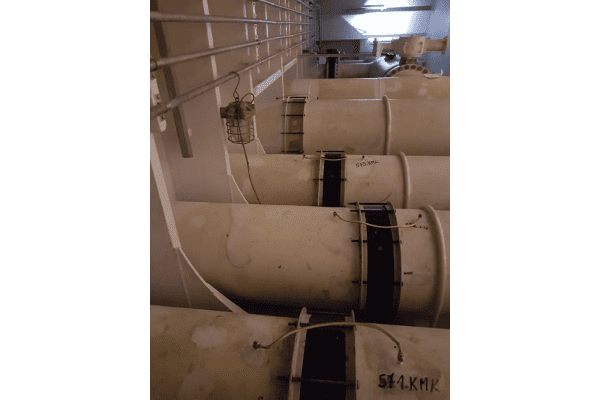

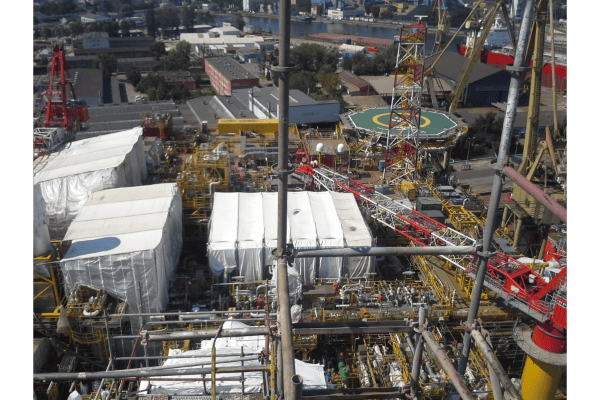

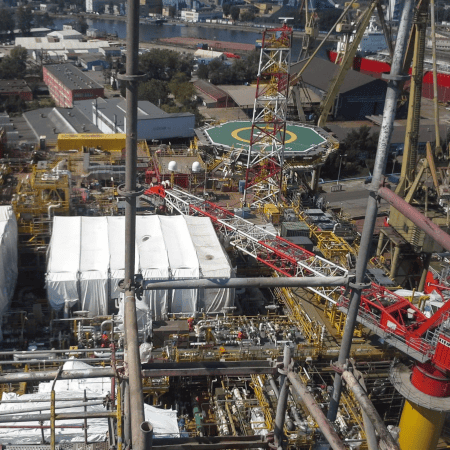

Projects

We present selected projects carried out for the industrial and shipbuilding sectors. Each photo is proof of our precision, reliability, and understanding of the specifics of working in challenging conditions. Thanks to our many years of experience and commitment, we deliver projects at the highest level, meeting the individual needs of clients in the industry.We invite you to explore the results of our cooperation with market leaders — each image tells a story of professionalism and reliability, which are the foundation of our activities.

International Cooperation

We operate not only in Poland but also successfully carry out projects in international markets — including Germany, the Netherlands, Sweden, Norway, Denmark, Switzerland, Wales, and China. Our experience and flexible approach allow us to meet the high demands of clients worldwide.

CheckContact Us

Invest Nord Service Sp. z o.o.

ul. Mikołaja Gomółki 2/60

80-279 Gdańsk

VAT ID: 5842782141

REGON: 382771299

Information:

info@investnordservice.com

Office:

biuro@investnordservice.com

Recruitment:

rekrutacja@investnordservice.com

Filip Długosz

CEO

Phone: +48 577 677

017

Email: f.dlugosz@investnordservice.com

Remigiusz Kreft

CEO

Phone: +48 577 848

788

Email: r.kreft@investnordservice.com

Agnieszka Czerwińska

Sales and Purchasing Department

Phone: +48 602 514

896

Email: a.czerwinska@investnordservice.com

Damian Kowalski

Business Unit Manager / Project Manager

Phone: +48 539 765

260

Email: d.kowalski@investnordservice.com

Nataliya Tuma

HR Department

Phone: +48 602 514

960

Email: kadry@investnordservice.com

Iwona Molasy

Accounting

Email: ksiegowosc2@investnordservice.com

Jakub Siwek

Phone: +48 534 414

704

Email: j.siwek@investnordservice.com